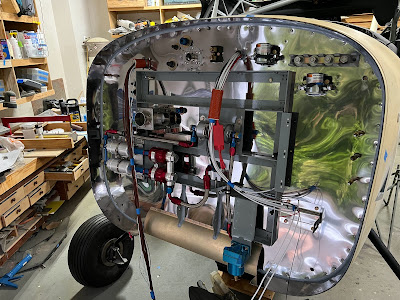

This has been a long journey. The build overall has been long, but the 'engine' journey from idea, to fuel system design and fabrication, engine mount, electronics placement, firewall decisions, firewall construction, engine on and off, etc has been 2 years. But, to see parts made 1 and 2 years ago come together is pretty darn cool.

While I am waiting for parts (more Ocrotek tape and 1 fitting), tidying up the wires, and adding a few more for later use. Might as well do it now while it is somewhat 'easy' to get to. Plus, tightening down and torque sealing all the bolts, brake fittings, etc.

Firewall went into today... hopefully for good! Was relatively easy... just a bit of prodding here and there to get it to seat into the fuselage.

The hardest part was fishing the wires through correctly. This wasnt that big a deal, except the EarthX battery jumper cables have to go through the opposite way because of the fusible link.

Next step is the fire barrier on the edges. I am taping everything off in stages so hopefully I can just let it gel, then pull the tape and have a nice line. I went with the 'gray' 3M Fire Barrier 2000+. Hopefully it looks OK.

Clecos in (for positioning, not that it was a problem - it all lined up perfectly after some gentle persuasion with a fist or two) and 2 or 3 lines of tape all around.

Fire barrier inserted between the firewall flanges and fuselage shell. I clamped in a couple areas where the clecos were not enough to snug it up enough.

Air deflector riveted and screwed in place (very thankful it still fit, as I drilled it over a year ago). Also all gooped up with fire barrier.

Its starting to look like something. Lots more to do... but the weekend is here! Hoping to get everything alive by end of day Sunday.

Almost there. Everything is functional at this point again (but only one battery). Pumps work, new starter relay works, everything through the firewall, etc. Lots of little things to do. Some fasteners to install, couple holes to drill, some rivets, etc. The interior of the panel can be reassembled as well. All of the fittings on the aft side of the firewall are populated. My goal is to get as much done as possible before the engine mount goes on.

Small issue with battery cables.

For my electrical configuration, the output of the main relays are bridged - IE they go onto a common bus. Because I want to be able to start off of either battery, the cable between then is a 2 gauge. Plus I have to tie in the engine bus, ACM, and fuse panel, plus the UL smoothing capacitor. Bottom line, there is a lot of stuff on the output side of the relays... and I have to add one more for the starter, and I just don't have enough threads left.

The thought: 2 terminal distribution block that I can tie in the big 2 gauge lugs, and then split off to the starter. All this means is the problem will not get worse. Need to find one that can handle a couple hundred amps. Then there is the issue of mounting location... I am out of room in that area, so it will probable have to be mounted to the engine mount with adel clamps.

Ready to re-hang the engine...

I took the opportunity to weight the beast before and after using racecar scales.

It wasnt quite perfectly level, but very close. Doesnt really matter for these purposes... what I wanted to know was the engine weight.

And the numbers are....

268 lbs for engine, exhaust, induction, starter, alternator / generator, etc. No baffles, intercooler, oil cooler, etc. An IO-390 weighs 310 lbs bare (no exhaust, no alternator, no starter, etc). Note: I forgot to take off the front travel plate (that mounts to the floor of the crate) when i weighed it. Its at least 2 lbs with hardware.

Couple points for anyone looking at UL:

- Turbo: You need to adjust the angle of the turbo outlet before mounting the engine. In my case, it was pointed straight up. Also, you have to remove the oil return line in order to spin in. Dont forget to tighten it back up (note to self).

- The main oil return line to the sump interferes with the right lower engine mount. I need to 'finesse' it a little.

- Engine umbilical to ECU, firesleeve, etc. Retest wiring.

- Oil cooler mount, cooler, plumbing, etc

- Baffles / plenum / intercooler ducting

- Intercooler plenum and hoses

- Cowl (oil cooler opening), reshape cowl for larger spinner

- Exhaust extensions

- CHT / EGT lines

- Plug wires

- Fuel delivery and return lines