I am at that point in the build where progress is frustrating because I have overcomplicated a lot of things. I decided to go with the Infinity Stick grips, and load up on functions on the grip itself. They are a really good grip it a lot of ways. Easy of installation and wiring is not one of them.

Well, thats not fair I guess. The installation is fairly straight forward... but you have to trim 1" off the stick to get it to fit under the panel, drill a big hole for a plastic bushing, and a slot for the wiring to pass through. But it nicely clamps onto the stick...

First things first... you need to set the fore / aft position of the stick. That means you need uphostery (which I ordered) first, then the sticks have to be drilled to the yoke. This is the part I have been avoiding because I was unsure how to tackle the issue. Since I have the fuel lines installed, you have to work around them.

So today after (what seems like months) of indecision (and talking to other builders), I tore into it. The holes have to be drilled through the yoke and stick, but I couldnt get my alignement jig on the yoke, so that means freehand drilling, which is prone to errors, plus you have to line up the sticks and I dont have the wings attached to center the ailerons. But, there is some adustment on the yoke, and turnbuckles. So I decided to just center the yoke with some wood blocks, center the sticks with a board (per the manual), and carry on bravely.

After marking 3/8" in from the yoke weldments, I drilled 3/32" pilot holes through the top only (yoke and stick) and clecoed them in. That should hold everything in place.

I dont have the right length drill bit for the forward hole, but did for the aft (again, working around the fuel lines). So both aft holes were drilled and a AN3-14 bolt dropped in replacing the cleco.

With the right length bolts I can proceed.

To the wiring. UGH.

The infinity grip the following options:

- 4 way hat switch

- Trigger switch

- Left and right thumb switches

- Middle thumb switch

- Pinky switch

After thinking a lot, and consulting the forum I decided on the following:

- 4 way hat switch: Pitch and roll trim

- Trigger switch - Push to talk

- Left and right thumb switches - Left(a): Autopilot disconnect / CWS. Right(b): Momentary toggle - forward, COM1 flip flop. Aft - COM2 flip flop.

- Middle thumb switch - Audio panel swap from COM1 to COM2 and vice verse.

- Pinky switch - Transponder IDENT

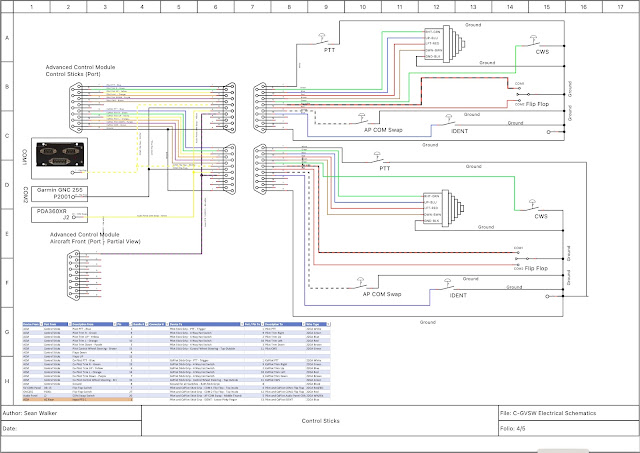

That equates to a whole bunch of wires. Items 1, 2, 3a are handled by the ACM wiring to the 'control stick' port. Items 3b, 4, and 5 need to be wired directly. The transponder IDENT will be handled through the ACM using a general purpose input.

Here is the wiring diagram for just the sticks.

This is not going to be fun. 10 lbs of poop in a 2 oz bag.

Grips mounted to the sticks after drilling.

Sticks fully drilled, ends cut and filed, grips mounted and wires fed through.

The Infinity Stick Grips are very nicely made, as assembled really well on top of the stick. After about 15 disassembles / reassemblies I am reasonable good at it. The issue is the wires... there are so many wires, and if they get caught in the channel for the stick, or against one of the bosses that the screws go through it wont go together. If any little thing is wrong, you are taking it all apart again. If you want a grip that you just mount on the top of a stick, this is not the one for you.

Next is to connectorize the cables from the sticks and integrate in the ACM, Dynon Radio, Audio Panel, etc. I thought I had enough connectors, pins and housings, but apparently not. Ordered from Digikey today.

Connectorizing was not fun (I have an aversion to connectors anyway, specifically getting pins out of shells - never goes well). There is a colour code for the wires, but there are duplicates. For the most part, black is ground (but not always), and there are multiple red and blue wires.

- Sorted through all the wires and found the ground (using an ohm meter), and separated them from the pack

- Tied all the ground together on the stick side using solder sleeves. There are 6 ground - so 3 into 1, then 2 into 1, then that wire went to the connector. Sleeves are hidden under head shrink.

- Checked functionality of every switch at all points in the process. Would really suck to get everything done and have a busted wire or bad ground.

- Connectorized the end using a d-sub 15.

- The connector will fit through, but without the shell, and it has to go through sideways. I left enough bare wire to get it through.

Onto final wiring. I have the ACM harness for each stick, but it doesnt come with IDENT, COM flip flops (x2) and Audio Panel swap. These all have to be added to the harness.

So I cut open the pilot side harness, and added the 3 wires. Oh what fun...

These 4 wires need to go to various places:

- IDENT: Goes to a PFD input on the AC Rear Connector

- COM 1 SWAP: Goes to the Dynon radio

- COM 2 SWAP: Will go to the yet to be purchased GARMIN NAV/COM

- Audio Panel SWAP: Goes directly to the Audio Panel.

To finally everything is done. Sticks are wired, connectors attached, everything tested good. Sticks are bolted in place.

Starting on the cleanup now. It sure needs it.