This will be a long post, written over many months...

I have built one instrument panel in the past, and honestly learned a lot. Both what works, and what doesn't work. That experience will serve me well (I hope).

Here are the decisions that need to be made:

- What is the mission? (IFR / VFR)

- Discrete instruments, or system

- Tentatively select components

- Determine real estate - how much room is there to work with.

- Do initial layout, and determine roughly what goes where.

- Test run. Sit in airplane with panel blank, with paper instruments. Its amazing what looks good on paper will not work when you are actually sitting in the airplane

- Refine design, incorporate changes from test run.

- Do actual mechanical layout.

- Wiring diagram / wire run list (pin to pin wiring table)

- Make panel inserts / structure

- Assemble / wire

- Configure / test

The first two answers are relatively easy.

- Mission: IFR. I do not have my IFR ticket yet, but my plan is to do it once the Sportsman is complete. At a minimum, I will wire everything but may not purchase a few components right away due to cost.

- Discrete Instruments or System: System. Currently planning on Dynon. I have Dynon is the Emeraude. They are 2 hours down the I-5, are super awesome at tech support and returns. All the pricing is pretty much the same. The big game changer is their Advanced Control Module that makes wiring way easier. The downside is they do not have a diversity transponder option, and do not support the uAvionix TailbeaconX.

Version 1.0 design

This is the end state... may take a couple phases to get here, but this is the goal - or at least something close to this.

This week I talked to Advanced Flight Systems and received a quote for their 'quick panel'. Honestly, I am struggling with the price a bit - not of the components, but for the ACM, wiring, and metal work. Its like $9500 USD for those 3 components. If you take out the ACM, its like 7K. I can build a lot of stuff for 7K. But on the flip side, its comes with all the documentation, panels are cut, painted, labeled, all wiring, switches, tested and ready to go. I can build a lot of stuff if I don't take 3 months to design and build a panel.

UPDATE: I worked the math and took into account the cost of the wire, switches, cutting, painting, labeling, etc and the cost differential goes to like $3600. This makes a lot more sense.

First piece of metal cut for the avionics... accessory tray!

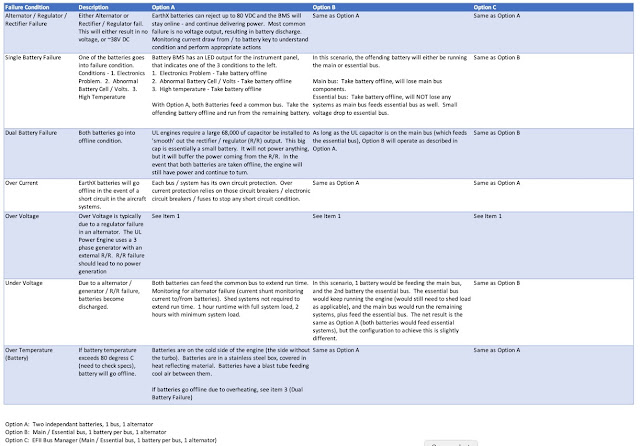

One of the big attractions to Dynon / AFS is their ACM (Advanced Control Module). It is the main wiring hub for the aircraft (except critical Engine wiring). Aides in wiring, troubleshooting, and future upgrades. On the downside, it is a single point of failure... But the architecture lends itself to not completely failing. It also has connections to a backup battery, that will keep the displays running.

Version 2 of the design is below... based on the AF-5600T.

Many changes from V1. Probably a few more versions to go... But I am getting closer. Plan is to order after Oshkosh 2021 - after seeing what is new / on special.

The only compromise I have made so far is the fuel gauge for the header tank. AFS (and Dynon for that matter) only support 4 tanks. AFS does not have any other input I can repurpose. But, with that said all I really care about is knowing if it is not full, or getting low. My plan was to put a capacitive probe in from the top down... I even bought the mounting flange.

Belite / Radiant makes an ultrasonic fuel sensor that mounts to the outside of the tank (no hole or fitting required - its bonded in place) that tells you if there is liquid there or not. They have 2 versions - one that works with their fuel gauge / computer, and one that has stand alone indicators. They have other ultrasonic senders that will give you quantity, but I don't have room for their gauge in the current layout.

https://radiantinstruments.com/bingo-4-liquid-detector/

My plan is to put 2 of their sensors in. One at 1/3rd tank, and one at 2/3rds. Green LED means good, red means bad. I think this fits the bill.

I thought about just putting a sight gauge in... but the top would be out of your field of view... in fact you would barely be able to see any of it. I think the sensor idea is a better solution.

Panel ordered from AFS on Tue, Aug 3 2021. ~4 month delivery.

Final panel design received from Advanced on Thu, Nov 1.

Very similar to my original design. Took 3 revs to get it perfect. The 3rd rev was text and hole alignment. It certainly does pay to have a design in mind when having it built.

Now its cutting metal, finishing, and wiring... hopefully will have everything by Xmas.

Below pic is from Advanced. They just received all the metal parts back from powder coat.

The instrument panel comes with pre-drilled holes that should line up with the horizontal tabs on the cage. They do not. To get it centered, it needs to shift to the left about 0.5". Asking Glasair and the forum for advice. Daniel Lodge on the forum recommended filling the unused holes, and putting a layer of glass overtop. That will be on the agenda for when everything comes out. I have some black pigment for resin coming, so it wont look to awful.

Today (Jan 14, 2022), Advanced sent me a picture of the panel assembled and mainly functional (missing switches). So very cool to see what is coming soon. Hopefully next week.

Jan 31, 2022: Panel is ready. Picking up from AFS on Fri, Feb 4.

Part II and III will cover the installation, wiring and testing.