The build manual gives to options for gear leg fairings. Aluminum or Fibreglass.

For aluminum, the fairing is two pieces (an upper and lower due to the flex in the spring gear), and wrapped over the leg, with a foam support structure to keep its shape, with a piano hinge on the aft side to hold it together. The brake line runs down the aft side of the leg, and holes are drilled in the foam for it to run through.

For fiberglass, the brake line is bonded to the aft side of the leg, and then foam is glued over top and shaped into an airfoil shape (using the front side of the leg as the leading edge). Fiberglass is layed up on top of the leg / foam, and then finished.

The kit comes with material for both options.

The below describes my 2nd attempt. The first didn't work out quite right. Close, but not close enough.

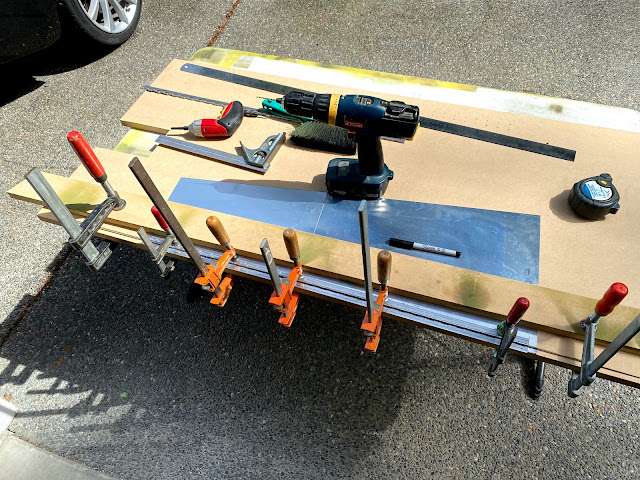

The trick here seems to be that you need the piano hinge to line up exactly the same on both sides. I accomplished this by laying both pieces of aluminum on the edge of a bench (leftover from my wing jigs). Clamped it down, and then laid the piano hinge down and drilled it in one piece over both sides - with the intent to cut it later.

At this point, the piano hinge is still one piece. I figure this is the best way to make sure it lines up. Need a small gap between the two halves so there is room for it to wrap around.

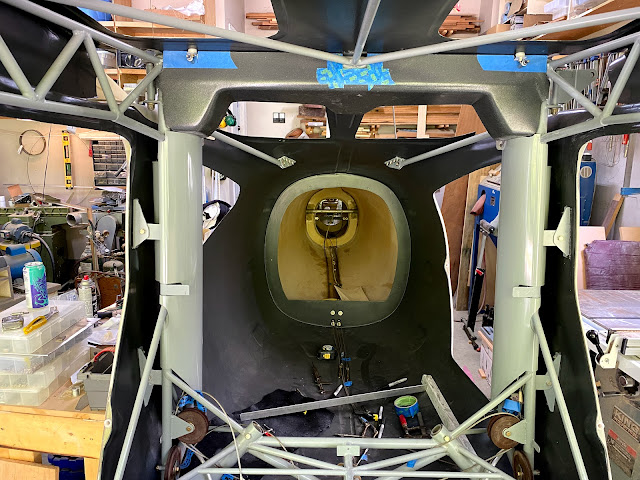

Two halves joined with the piano hinge. The alignment is pretty good. The lower half needs a small trim on the trailing edge for them to line up perfectly. The nice thing is its super easy to see now. Will take it to the sheer in a couple days.