Now the wiring begins.... I both love and dread this part. Love it because it makes things work, and dread because compromises will need to be made.

Step 1: Electrical bus(ses).

Target is 3:

1. ACM - which includes avionics, lights, pitot heat, etc. Everything that the ACM powers, which is everything but engine.

2. Engine bus. Stand alone bus for the engine, using breakers.

3. Everything else bus. This will be fuses, and for things that dont really matter - like seat heaters. This will be the last priority.

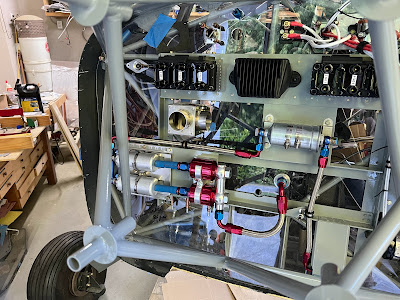

The output of the two batteries goes to a central point, which is the current shunt. This shunt will measure the total input / output to the batteries and will be inclusive of everything. From the shunt, power goes 3 ways - to the ACM, Engine Bus, and to a fuse panel.

Fuel Pumps

The UL Power ECU has the provision to 'control' the fuel pump (or pumps) via a relay. The ECU drives the coil on the relay (Fuel Pump Control Relay - FPCR), so it can turn the pumps on or off. This is useful when on the ground working on things. The system will pressurize, then the pumps shut off.

However, what if the relay fails? So my fuel pumps switches have an 'auto' position (which goes through the relays) and 'force', which does not go through the FPCR. Overkill? maybe.

Everything else engine needs to wait until it arrives - hopefully in late May.

From a wiring perspective... 2 power feeds from each of the pump breakers. 1 feed goes directly to the switch, one goes to the FPCR. The center position of the switches goes to the pumps. The pump wiring is on a connector as the whole fuel pump tray is removable (kinda - have to take the header tank out first).

Header tank sensors.Well this has been fun. The sensors I bought from Radiant are cool, and I tested them very thoroughly with water to ensure they do what they should do. But their connectors are, lets say, interesting.

The sensor is connected with a USB cable. The head unit (of which I have 2) has the power connections. Plus the cable lengths were way too long. So I shorted everything up and put them both on one connector.

They are temporarily wired to power off a breaker to verify the wiring and connector. Debating whether to power them from the ACM or a breaker or fuse. Probably the ACM long term.They flash red when liquid is not present. Obviously the tank is empty, which is a good sign.Radient recommends siliconing the LED's into the holes. Not sure if I am going to do that, or make a mount.

ACM and Pre-Built Harnesses

I love the ACM. I love the harnesses. I have to figure out how to tame them.

To start, I plugged everything in. No wires are tied in anywhere. Just wanted to get the lay of the land (so to speak). Holy crap, its a lot of wires and I am nowhere near done yet.

Dont judge me based on these pics. Please.

The plan is to figure out where everything will go, then take it all apart and finish the trays and brackets, then reassemble for good. But I have to build the aircraft front, rear, and wing harnesses. Everything is ordered to do that.Main Power Distribution

OK - this is a mess. But you have to start somewhere. Again, the purpose was to figure out what goes where.

Two EarthX ETX900 batteries, two master relays with flyback diodes. Each battery can be switched in or out. This is all pseudo temporary, but it works.The output of the two relays is bridged together, and the starter will come off here. From the bridge point, goes to the main shunt with 6 gauge wire. From there, goes to the ACM and engine bus. The battery, aircraft frame, and engine all tied to a single firewall ground point. Also a 10 gauge wire to the avionics bay ground bus. This may need to increase to 8 gauge.

Engine Bus

As the ACM shies away from anything 'engine' related, I decided to have breakers for everything engine and fuel related.

10 gauge wire coming from the main current shunt on the hot side of the firewall. It passes through a Hall effect sensor, so I will know (in theory) the current draw of everything engine / fuel related (but I won't know what is drawing what - just the total).The Hall effect sensor is mount under the starboard avionics tray. This may have to move simply for serviceability. It will be very difficult to change - if not impossible. On 2nd thought, if the MFD is removed there is a clear shot to it, but all of the wiring is not yet installed so that may change. Time will tell.Harnesses to build

- Aircraft front: Comprises of prop controller, taxi lights (which will go to the wings - but that is a different story), cabin lights, panel fans, belly strobe, elevator trim.

- Autopilot servos: These are pre-built from Advanced, need to be terminated on servo end.

- Sticks and flaps: PTT, AP disconnect, IDENT, flip flops, Audio Panel switch, flap position potentiometer

- Wings (aka Aircraft Rear): Pitot heat, landing / taxi lights, nav / strobes, fuel transfer pumps

- Engine sensors: EGT, CHT, Fuel Pressure, CANBUS (to ECU, which has a large number of sensors), fuel tank sensors, etc.

The panel has taken a bit of a back seat due to waiting for a new panel from Glasair. Should be here August 9th, then I have to recut it all over again.